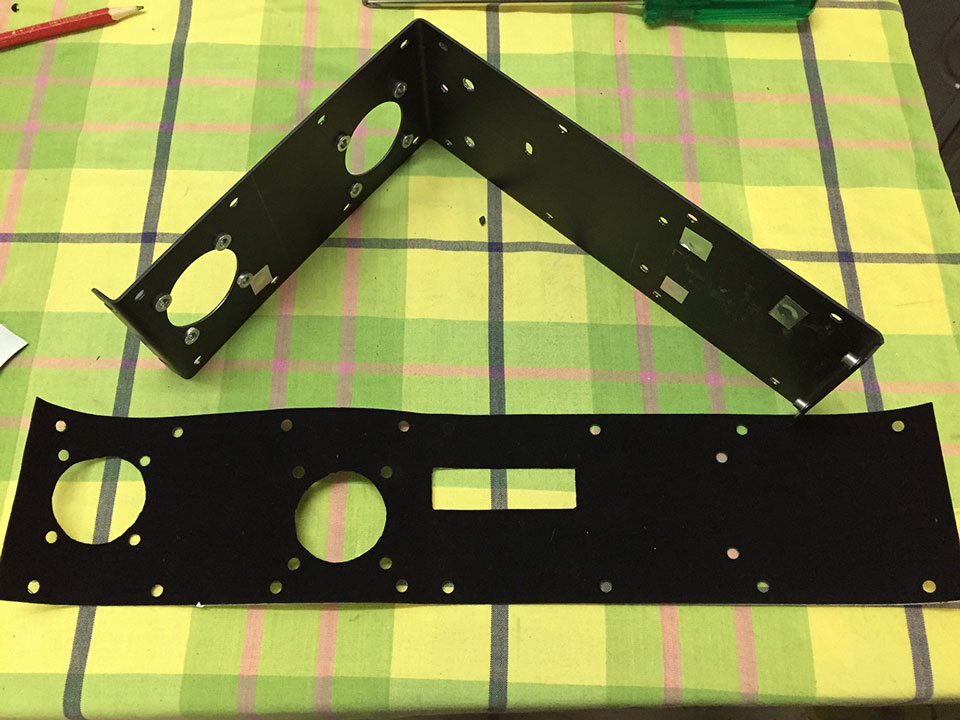

1. Light protection

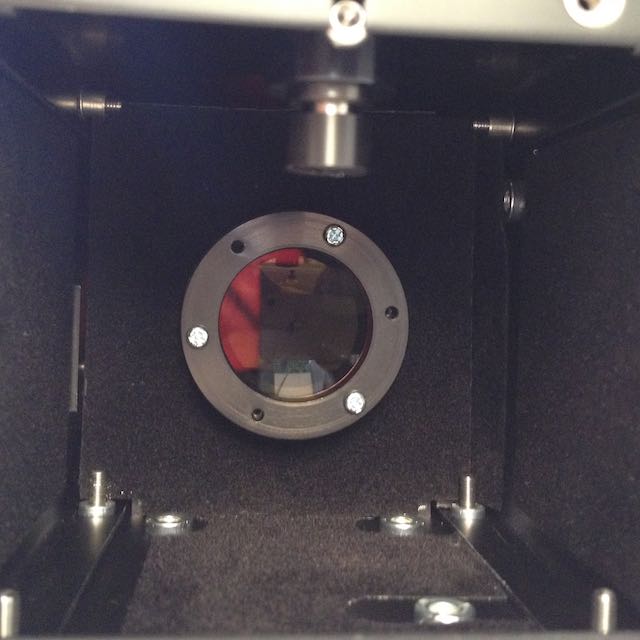

The “Heathcote Light Shield”. A quick removal, lightweight felt lined box that provides protection against inherent light leaks around the diffraction grating assembly.

Flocking around the diffraction grating to minimise internal reflections:

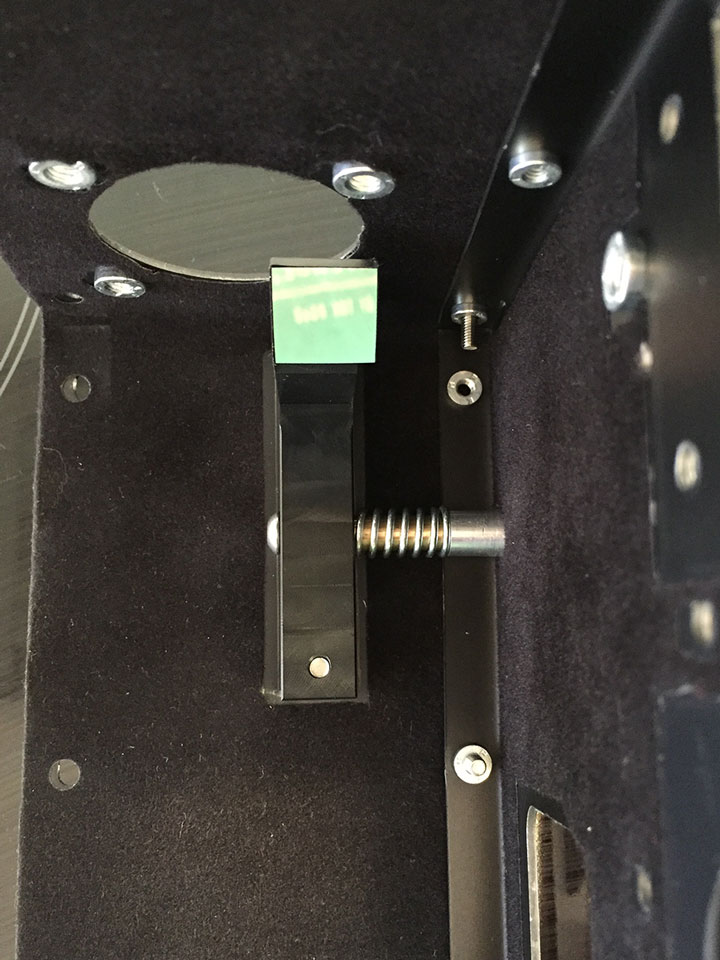

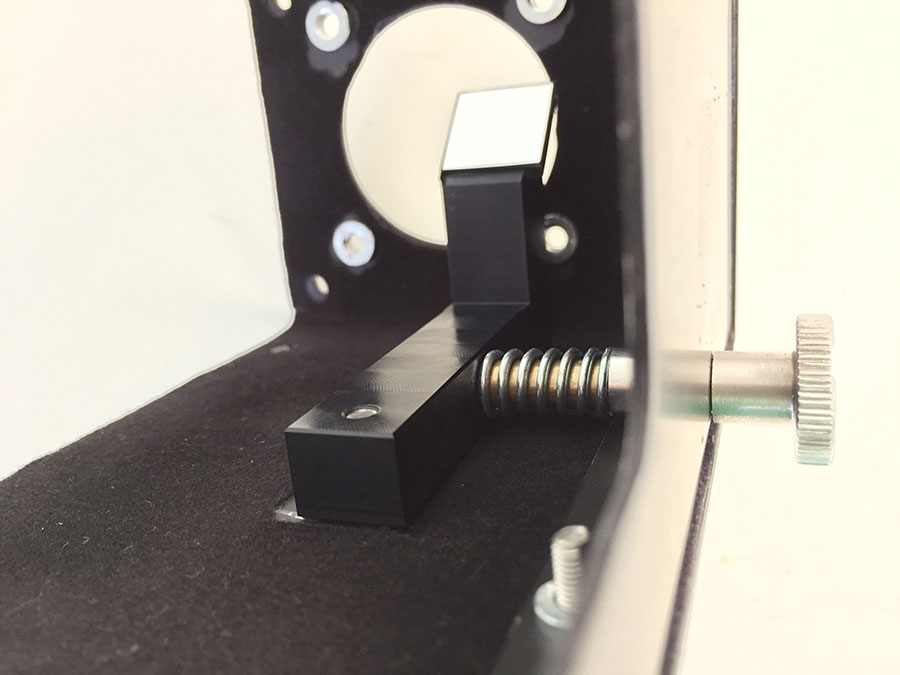

2. Guide mirror adjustment

Spring loaded guide mirror collimation screws to make adjustment much easier:

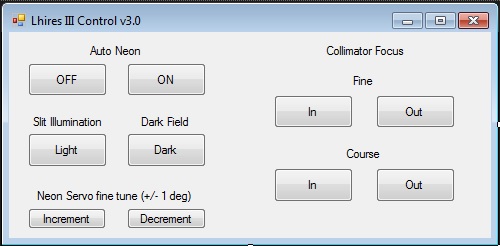

3. Neon automation

3. Neon automation

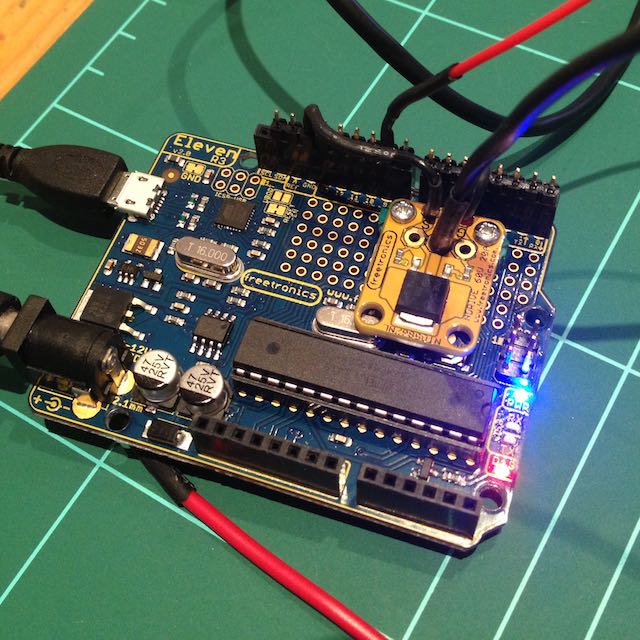

The motorised neon assembly uses an Arduino Uno circuit board for driving a micro servo, together with a mofset for controlling 12V DC power to the neon lamp driver.

The servo is mounted to a bracket that allows a simple ‘push fit’ into a reversed servo horn attached to the output of the existing neon shaft. The assembly is held in place with a single hex screw. Power and USB are at the rear of the circuit housing. A Visual Basic program provides control of the neon assembly, and future collimator focus.

A close-up view of the reversed servo horn assembly. The idea, adapted from the design by Stephane Ubaud is self explanatory.

4. Motorised collimator focus

Step 1 – Mounting the main gear. A spur gear bored to 40mm internal diameter held onto the existing collimator lens barrel with 3 screws set at 120 degrees.

Next steps … internally mounted continuous rotation micro servo (under construction).

5. Mirror adjustment

This modification utilises a spring mounted screw for precise pivot adjustment of the main mirror.

6. Internal flocking